Common Breakages in Physiotherapy Treatment Tables: What to Look Out For and How to Avoid Costly Repairs

Choosing the right treatment table for your physiotherapy practice involves more than just considering the immediate price tag or appearance. Knowing what parts are prone to breaking can save you from unexpected downtime and costly repairs. Here are some of the most common issues that can occur with treatment tables and tips on how to avoid them.

1. Motor Malfunctions

The motor is the heart of your treatment table, responsible for adjusting height and other movements. A motor failure can lead to an urgent situation, causing significant disruption to your practice. When choosing a table, always ask about the brand of motor used. If the manufacturer is uncertain, it could indicate that replacement parts might be hard to come by in the future. Our top recommendation is a German-made Hanning motor, known for its reliability and availability of replacement parts.

2. Switch Failures

Switches on treatment tables can be another source of trouble, especially in wired systems with switches positioned all around the table. This setup might seem convenient at first, but it can be a headache if a switch fails. Identifying which switch caused the issue can be difficult, often requiring an expensive repair by a technician. To avoid this, opt for a table with a simpler system like the Hanning motor, which uses air pressure instead of complex wiring. This design reduces the risk of switch failure and eliminates the need for extensive repairs.

3. Upholstery Wear and Tear

Upholstery on treatment tables is another area that can deteriorate over time. The durability of upholstery is measured by its rub count. Inexpensive treatment tables often use vinyl with a rub count below 200,000, leading to early wear and tear. High-end Canadian-made tables, on the other hand, have rub counts exceeding 2 million, ensuring greater longevity. When purchasing a table, inquire about the rub count to ensure you're getting a durable product.

4. Gas Strut Issues

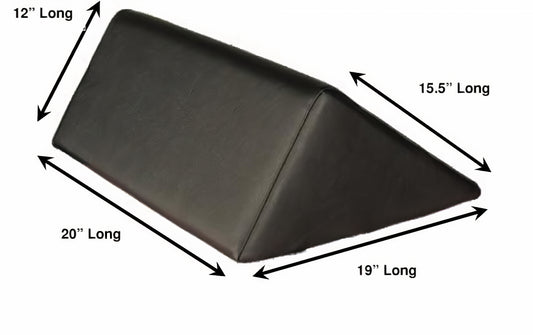

Gas struts are used to assist with adjustable sections of treatment tables. Over time, these struts can lose compression, leading to sagging sections. Replacing them can be costly, with each strut costing about $250 each and a table potentially has up to four struts. Consider choosing a table with friction locks instead of gas struts. Friction locks use a simple wedge design, providing longer-lasting durability and reducing the need for frequent replacements.

Conclusion: Choose a Table That Stands the Test of Time

When selecting a treatment table for your physiotherapy practice, consider not only the initial cost but also the potential for future repairs and maintenance. Look for a table with a reliable motor, minimal wiring in its switches, high-quality upholstery, and durable components like friction locks instead of gas struts.

At HealthMed our most recommended high end table is the treatment table line by Kor Innovations. These treatment tables prioritize durability and quality. Physiotherapy plinths by Kor Innovations feature the trusted Hanning motor, air pressure-based switch systems, high-rub-count upholstery, and friction locks for a simple yet robust design. By choosing Kor Innovations, you invest in a table that is built to last, reducing the risk of costly repairs and ensuring your practice runs smoothly for years to come.